Seminar: Chemical Looping Technology

9.25.18

Today Dr. Fan came from Ohio State University (OSU) to give a departmental talk about chemical looping platform technology that his group has been developing. This carbonation calcium hydrogen looping talk for the most part wen over my head, but I did learn some cool things that I would've never have thought about before!

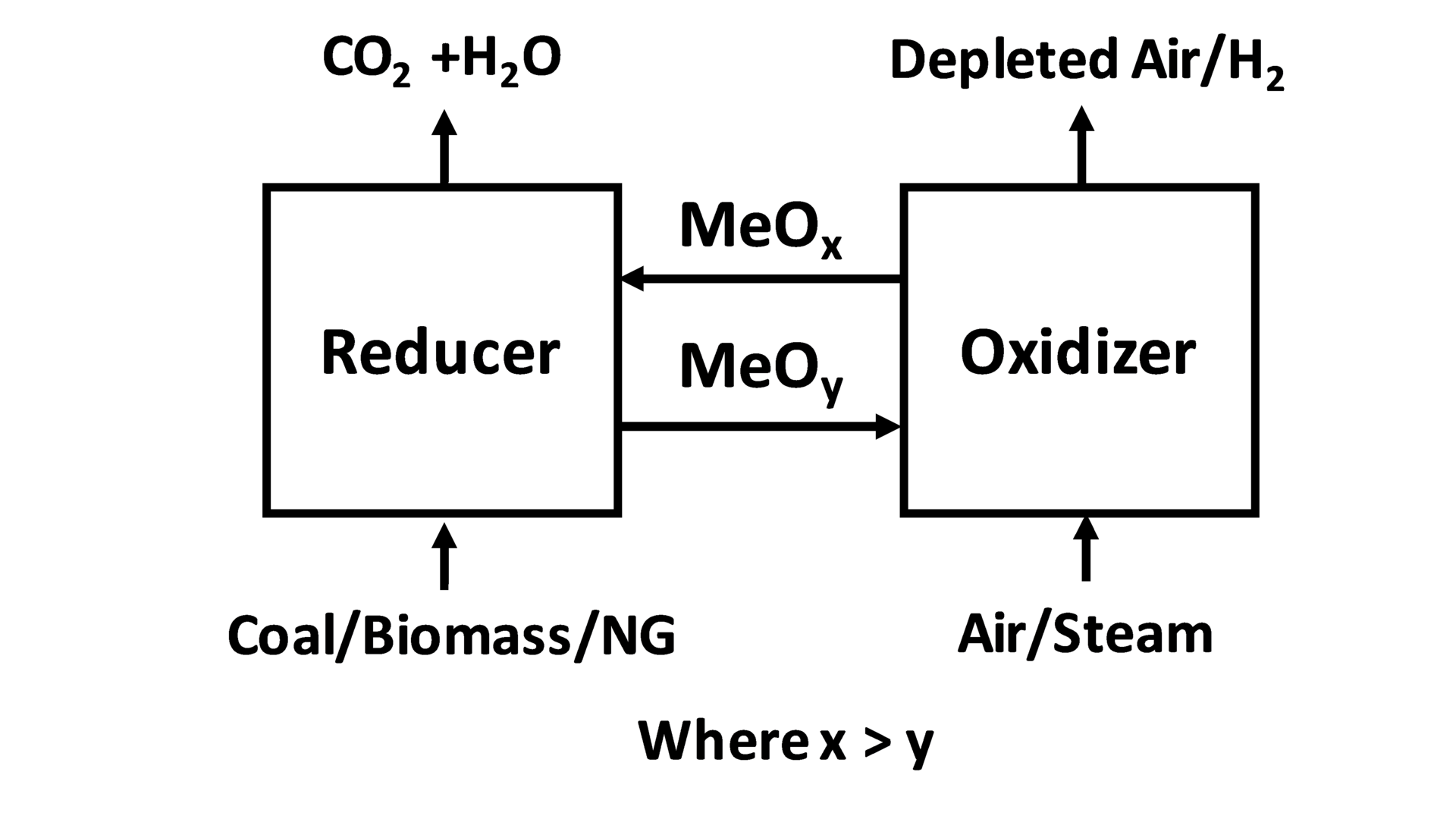

The looping technology was designed for an ITRI plant in Taiwan that's located directly next to a limestone mountain, its purpose it to produce hydrogen gas for energy storage. Within this redox process a transition metal oxide acts as an oxygen carrier and either goes through combustion, gasification, selective oxidation, or acts as a water splitting catalyst. Throughout the years Dr. Fan talked about how there have been different processes for this hydrogen gas production such as the Lewis and Gililand, IGR HYGAS, and CO2 Acceptor processes. Many different companies have implemented these at various stages including Chalmbers, Humosa, and Dupont; with the later having to dynamite their materials because it was impossible to discharge the metal oxide after use as it had melted.

He then went on to explain that the messy and costly processes of the past can be improved with his research. OSU's oxygen carries are sustainable for over 3,000 redox cycles among other exiting properies.

- Can be packaged for cheap.

- They burn coal strategically and produce no CO2

- CO2 as a partial substitue for methane feedstocks gives a CO2 negative process.

- This isn't a catalytic process

He then went on to show how his lab's particles flow in the opposite direction to the gas feed, similar to both a heat exchanger and a chromatography column in my opinion. This is also similar in my mind to a multi-state gas absorption column, but each stage is each individual OSU particle. CO2 can be used as the feedstock, but is methane is used "we need the methane to have a low adsorption energy but a high activation energy so that it can actually be released." This particular sentence went over my head, but I'd be interested in learning more about this in the future.

Right now, student run the pilot plant down in Louisiana, taking some time off of their coursework and have that time count as either fieldwork, or research. I think that this is a really great example where acadamia and industry collide, especially as I ask myself what I want my path to be. I think this connects moreso to the mass transport that I'll learn in the following semester, but is interesting nevertheless because of how niche certain subjects can go. This is something I've never thought of, and yet, was completely interesting. I think this really shows how chemical engineers are well rounded, and are first and foremost problemsolvers.

Photos taken from Fan's paper here.